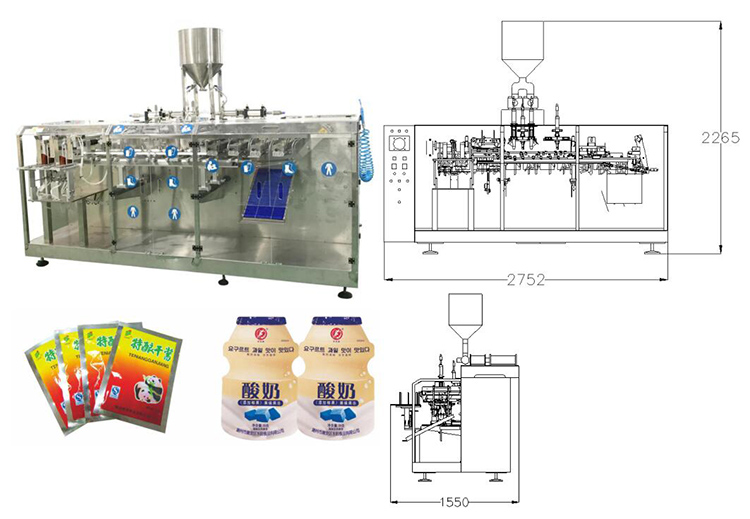

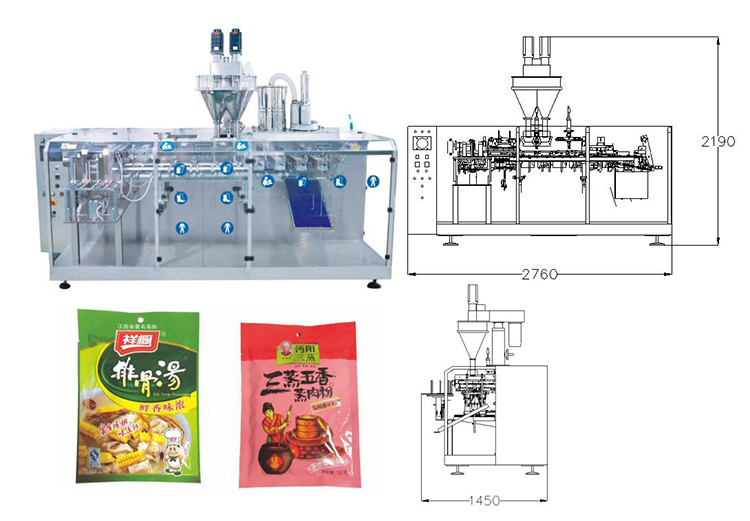

OCL-140S 水平式雙給袋包裝機(jī) Horizontal double-to-bag packaging machine

全國(guó)服務(wù)熱線(xiàn):

159-1595-6886(微信同號(hào))全國(guó)服務(wù)熱線(xiàn):

159-1595-6886(微信同號(hào))主要特點(diǎn):Main feature

1、粉料物料計(jì)量包裝系統(tǒng)有水平式給袋包裝機(jī)與下料系統(tǒng)組成;

1. The powder material metering and packaging system consists of a horizontal bag-feeding packaging machine and a blanking system;

2、放袋槽放袋方便簡(jiǎn)單,配備自動(dòng)壓袋裝置;

2. The bag-putting slot is convenient and simple for bag-putting, equipped with automatic bag-pressing device;

3、配置進(jìn)口壓力感應(yīng)裝置,達(dá)到不下料不封的效果,節(jié)約包裝袋;

3. Equipped with imported pressure sensing device to achieve the effect of no blanking and no sealing, saving packaging bags;

4、雙給袋包裝系統(tǒng),包裝速度更快、重量更準(zhǔn)確,采用高質(zhì)量的配件,保持機(jī)器的持久穩(wěn)定;

4. Double-feed bag packaging system, faster packaging speed, more accurate weight, and high-quality accessories to keep the machine stable;

5、采用彩色觸摸式顯示屏,簡(jiǎn)單操作,多功能設(shè)計(jì);

5. Adopting color touch screen, simple operation and multifunctional design;

6、機(jī)器采用不銹304L外觀,碳鋼機(jī)架部分與部分配件做耐酸、耐鹽防腐處置層加工。

6. The machine adopts the appearance of stainless 304L, and the carbon steel frame part and some accessories are processed with acid-resistant, salt-resistant and anti-corrosion treatment layer.

7、選材要求:大部分配件以模具化生產(chǎn)成型,主要材料選用304不銹與氧化鋁。

7. Material selection requirements: Most of the accessories are formed by mold production, and the main materials are 304 stainless steel and alumina.

8、可選配各種打碼、噴碼、排氣、沖孔系統(tǒng);

8. Various coding, coding, exhaust, and punching systems are optional;

適用范圍:Scope of application

本機(jī)包裝類(lèi)型:Native packaging type

01.固體類(lèi):糖果、花生、青豆、開(kāi)心果、膨化食品等固體類(lèi)物料的包裝。

01. Solids: packaging of solid materials such as candies, peanuts, green beans, pistachios, puffed foods, etc.

02.顆粒類(lèi):豆類(lèi)、結(jié)晶味精、結(jié)晶鹽、顆粒狀藥品、膠囊、種子、化學(xué)調(diào)料、雞精、瓜子、農(nóng)藥、肥料、飼料等顆粒類(lèi)物料的包裝。

02. Granules: beans, crystalline monosodium glutamate, crystalline salt, granular medicines, capsules, seeds, chemical seasonings, chicken essence, melon seeds, pesticides, fertilizers, feed and other granular materials.

03.粉劑類(lèi):調(diào)味品、奶粉、素食粉、五谷粉、葡萄糖、生粉、面粉等粉劑物料的包裝。

03. Powders: packaging of condiments, milk powder, vegetarian powder, grain powder, glucose, corn powder, flour and other powder materials.

04.液體類(lèi):醬油、米醋、果汁、飲料等液體類(lèi)物料的包裝。

04. Liquids: packaging of liquid materials such as soy sauce, rice vinegar, fruit juice, and beverages.

05.醬體類(lèi):番茄醬、辣椒醬、豆瓣醬等醬體類(lèi)物料的包裝。

05. Sauce body: packaging of ketchup, chili sauce, bean paste and other sauce body materials.

本機(jī)技術(shù)參數(shù):Technical parameters of this machine

| 包裝速度 Packaging speed | 30-90bags/min |

| 總功率 Total power | 5KW(單主機(jī) Single host) |

| 包裝尺寸 Package Size | 100-250mm/90-140mm(L*W) |

| 供電電源 Power supply | 380V |

| 整機(jī)重量 Total Weight | 2000KG |

| 包裝容量 Packing capacity | 10g-400g |

| 耗氣量 Air consumption | 0.7m3/min |

| 外形尺寸 Dimensions | 2760*1550*1350mm |

| 包裝袋類(lèi)型 Bag type | 自立袋、四邊封袋、拉鏈袋、手提袋、紙袋等各種預(yù)制袋 |

| Various prefabricated bags such as self-supporting bags, four-side sealing bags, zipper bags, handbags, paper bags, etc. |

本機(jī)主要配置:Main configuration of this machine

| 01.氣動(dòng)元件:Pneumatic components | |

| 給袋汽缸:To bag cylinder | 臺(tái)灣亞德客AirTAC Taiwan |

| 其他汽缸:Other cylinders | 臺(tái)灣亞德客AirTAC Taiwan |

| 氣動(dòng)電磁閥:Pneumatic solenoid valve | 臺(tái)灣亞德客AirTAC Taiwan |

| 真空壓力表:Vacuum pressure gauge | 臺(tái)灣亞德客AirTAC Taiwan |

| 氣管、接頭、三聯(lián)體:Trachea, joint, triplet | 臺(tái)灣亞德客AirTAC Taiwan |

| 02.電氣元件:Electrical components | |

| 顯示屏(觸摸屏):Display (touch screen) | 臺(tái)灣威倫Weilun |

| 編碼器:Encoder | 日本歐姆龍Omron |

| 變頻器:Frequency converter | 深圳金鐘Shenzhen Admiralty |

| 控制開(kāi)關(guān)、按鈕、繼電器:Control switches, buttons, relays | 法國(guó)施耐德Schneider |

| 光電檢測(cè)元件:Photoelectric detection element | 奧托尼克斯Autonics |

| PLC: | 億維Edimensional |

| 中間繼電器:Intermediate relay | 美國(guó)ABBAmerican ABB |

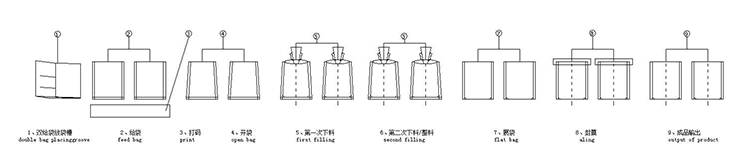

包裝工藝流程圖:Packaging process flow chart